When your factories need onsite equipment repairs during maintenance shutdowns Selectro can come and maintain, repair, and restore your machinery in a timely, cost-effective manner. Our process means your factories will experience less downtime due to breakdowns and will also extend your maintenance budget.

Selectro’s metal repair process reclaims your components for another full life cycle. We can easily repair and resize components to their original dimensions. Often the repair will contain a harder wearing material than the original part and will therefore last longer. This process can also provide erosion protection for exposed metal in harsh environments.

Apart from being able to keep your original OEM part for a longer period of time, using selective electroplating for your repairs is more economical, has a faster turnaround with less downtime, and cannot be messed up through an order mistake, version differences, or shipping errors and delays. The repaired and enhanced OEM will fit perfectly back into your machine every time. Continuously throwing out and replacing your O.E.M parts costs a lot of money. Through electroplating, your O.E.M part can be restored, which saves you money and is far more efficient.

Each selective electroplating application is unique, and therefore each repair will be thoroughly considered and performed by trained, knowledgeable technicians, ensuring quality and reliability for years to come.

Electroplating in Action

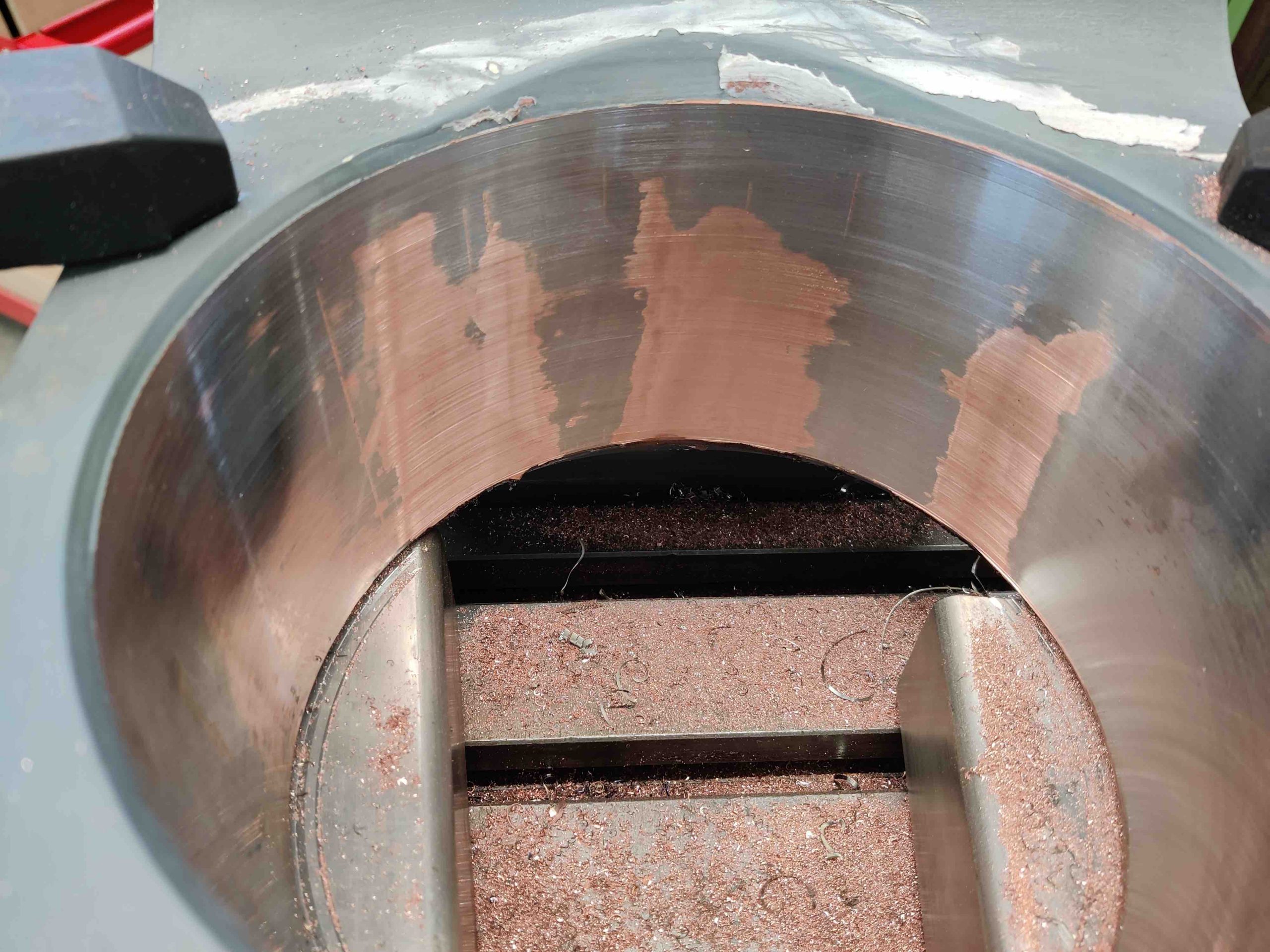

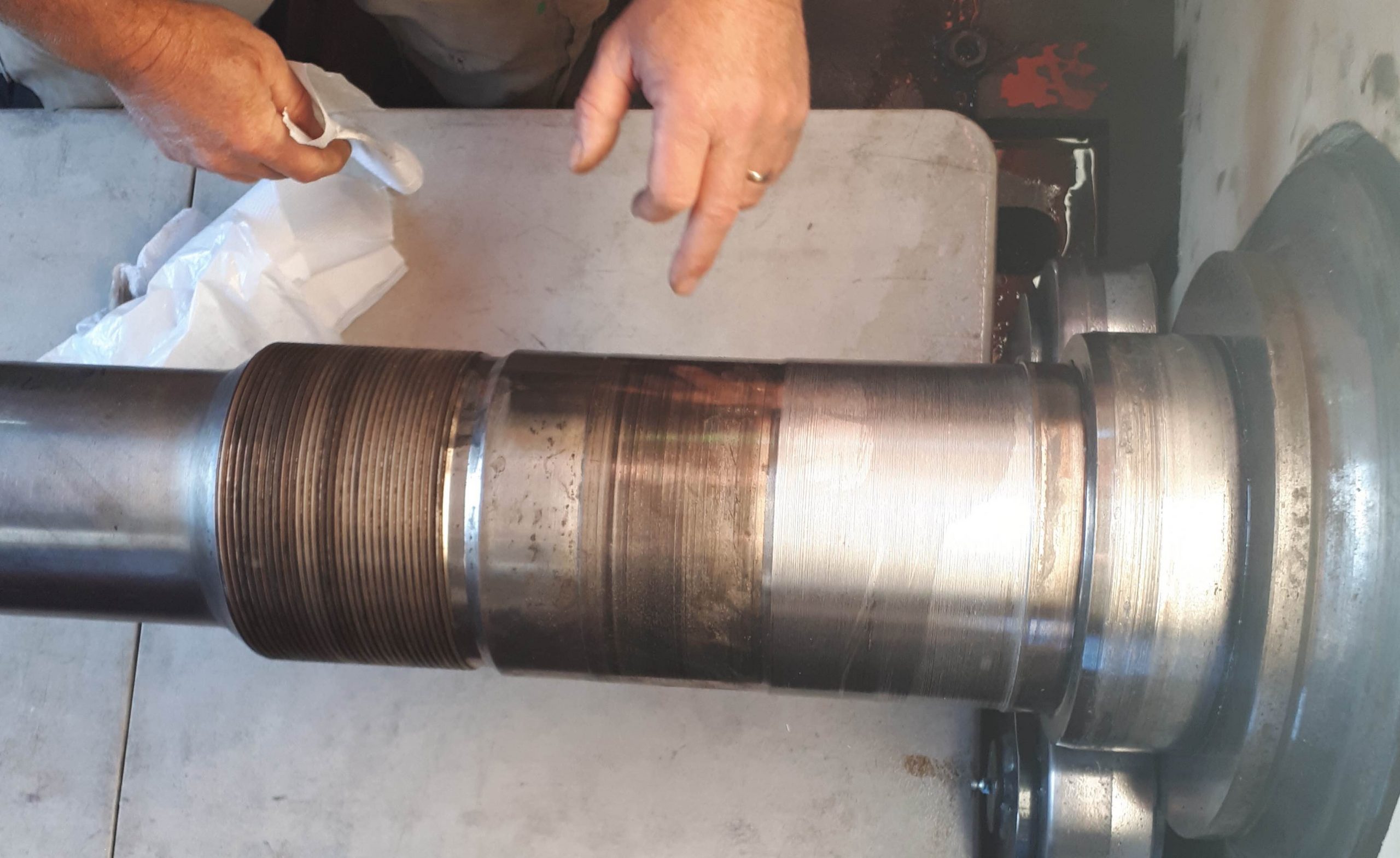

Examples of our Work

See the before and afters of some of our previous projects. To see the before images, slide the centre line of the images to the right. To see the afters drag it to the left.