Selectro’s metal repair process reclaims your components for another full life cycle. We can easily repair and resize both seal and bearing surfaces to original dimensions. Often the repair will contain a harder wearing material than the original part and will therefore last longer. This process can also provide erosion protection for the exposed shaft in harsh environments e.g. Marine and fishing boats.

Apart from being able to keep your original OEM part for a longer period of time, using selective electroplating for your bearing journal and seal surface repairs is more economical, has a faster turnaround with less downtime, and cannot be messed up through an order mistake, version differences, or shipping errors and delays. The repaired and enhanced OEM will fit perfectly back into your machine every time.

We can repair many different bearing journal and seal surface systems including:

Input and output shafts – gear box

Pump shafts

Motor shafts

Roller shaft ends

Gear shafts

H vac fans

Quarry machinery

Metal crushers

Lifts and hoists

MVR – steam seal surfaces

Some transmission components

Marine – drive shafts and steering. Propellor shafts

Axel shaft – from 4-wheel motorbikes up to rock truck

Steering and sector shafts

Electroplating in Action

Examples of our Work

See the before and afters of some of our previous projects. To see the before images, slide the centre line of the images to the right. To see the afters drag it to the left.

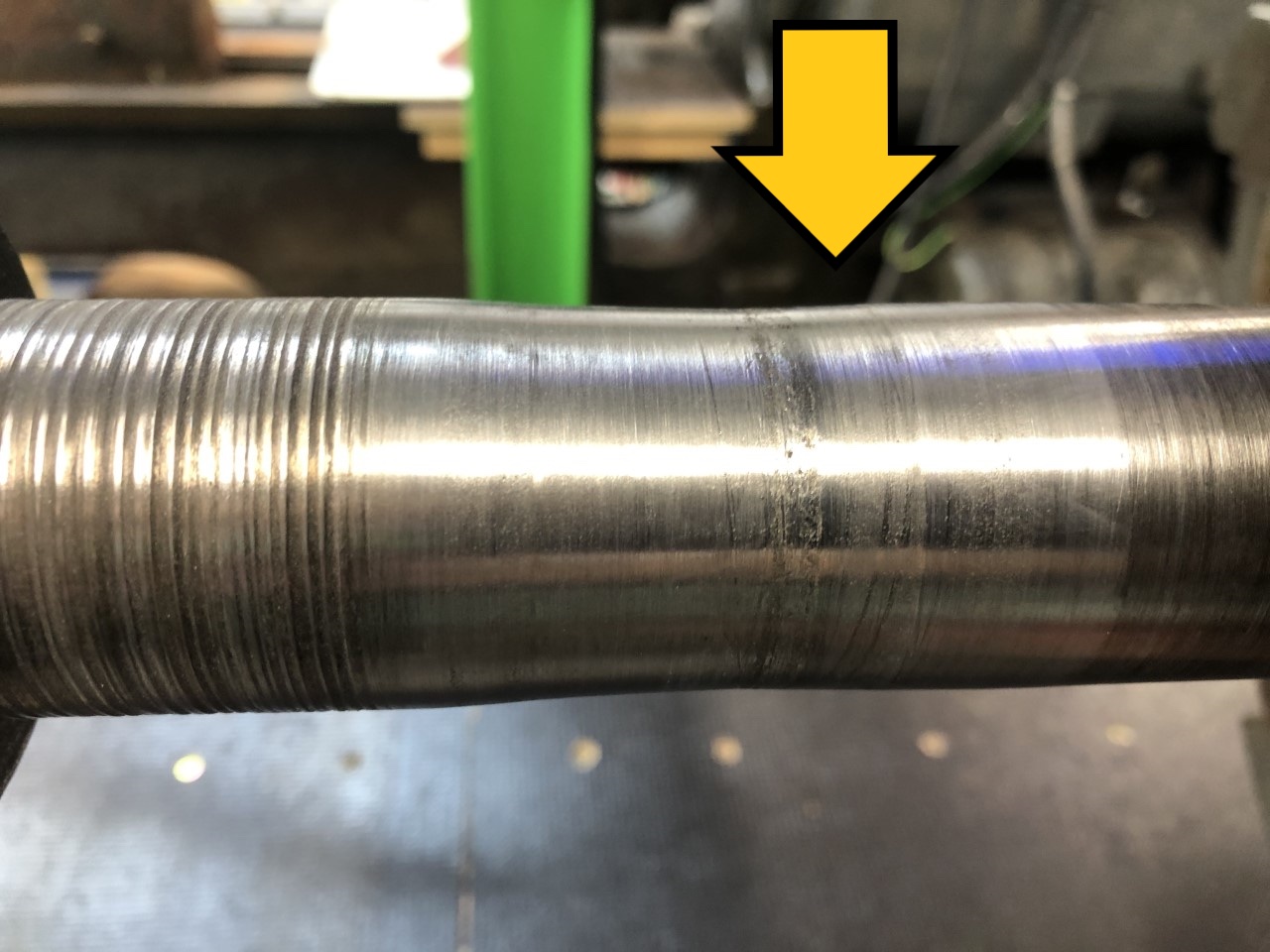

Output Shaft – Lip Seal Wear

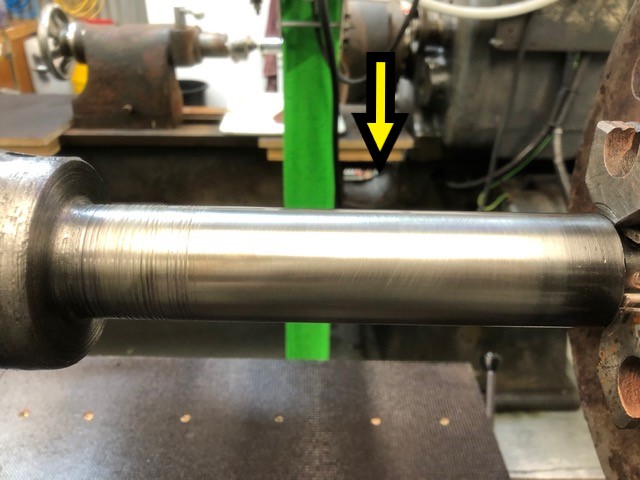

Axle Bearing Journal

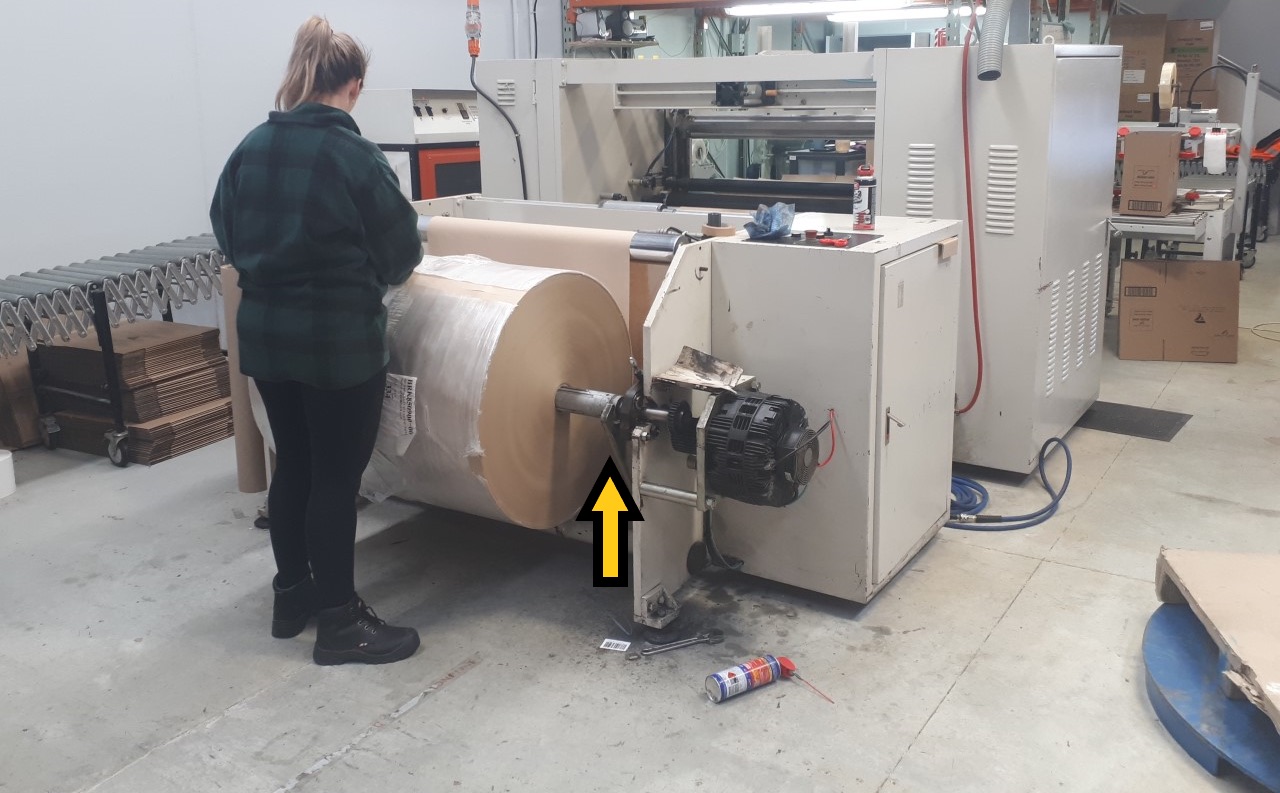

4-Wheel-Drive Axle

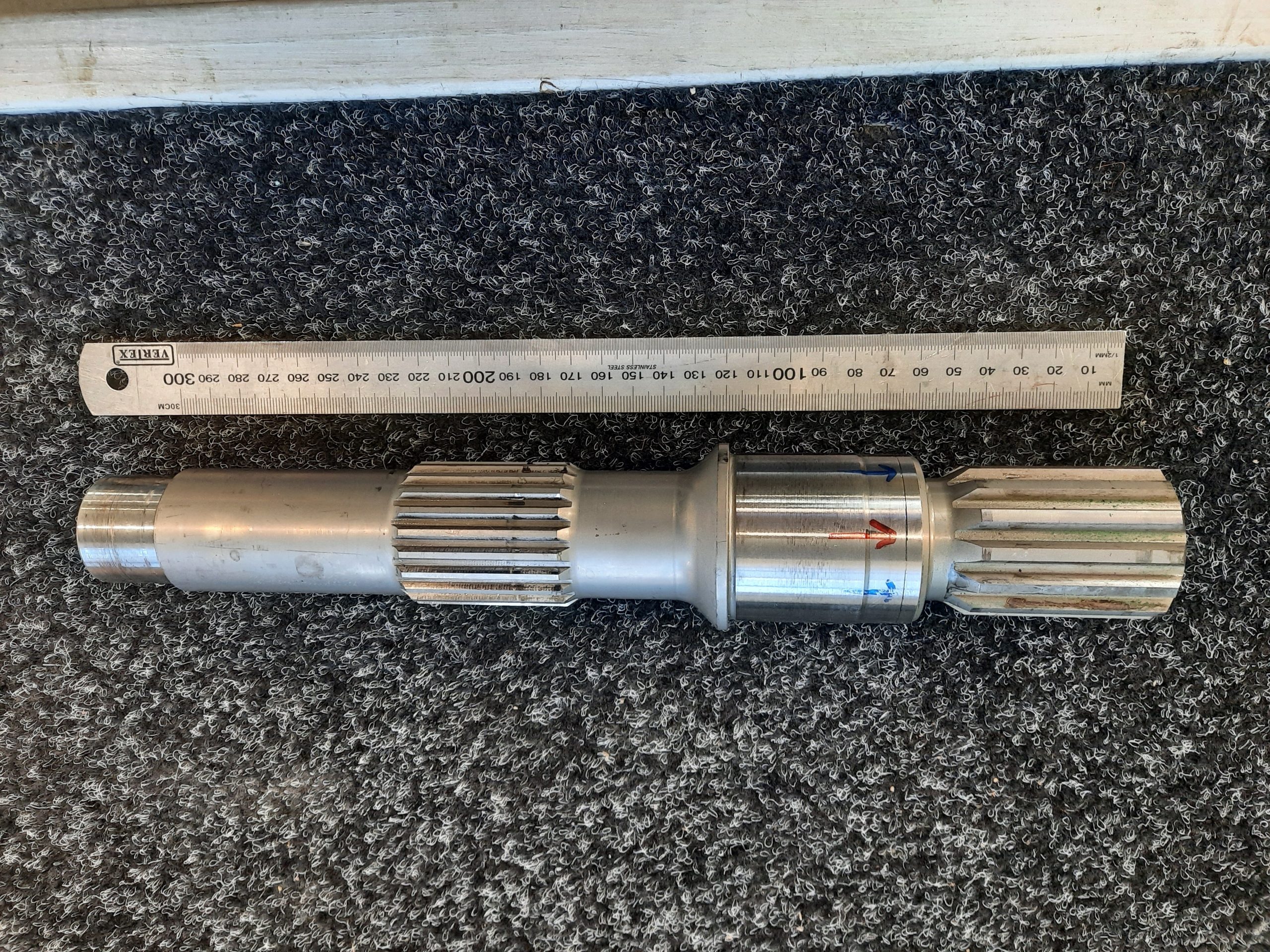

Spline Shaft

Output Shaft – Pitted Seal Corrosion

Ball Valve Resurfacing

Output Shaft

Axle

Oil Pump Shaft

Drive Shafts 4WD

Input Shaft G/B