When the chrome rod component of your hydraulics system sustains damage to a specific area but the rest of the rod is still fit for service, it makes more sense to carry out a patch repair rather than replace or re-chrome the entire item.

There can also be corrosion and pitting inside the cylinder near the opening of your hydraulic systems where moisture may collect. If the diameter opening is large enough to fit our tooling inside, we can also repair the internal surface.

When repairing your hydraulic systems, Selectro uses a nickel cobalt alloy which is hard wearing (48 Rockwell), is very dense, and provides high corrosion protection. This thin layer of nickel cobalt alloy will protect the chrome from moisture penetration and is also excellent for rods that are exposed to saltwater environments.

If the equipment is large or dismantling is difficult or expensive, then our mobile service can come to you. The mobile option can be a real advantage if equipment downtime is a problem.

We can repair many different hydraulics systems including:

Forklift masts

Excavator and heavy machinery

Crane/HYAB

Agriculture machinery

Forestry and milling machinery

Transport machinery

Fixed plants

Port equipment

Marine cranes

Hydraulic Spoil Valves – we can repair the worn seal surfaces and make them work like new again.

Hydraulic motors – shafts and housings

Hydraulic hose and crimping tools – remove scores and pits from inside the housing cylinder.

Power steering shafts

Electroplating in Action

Examples of our Work

See the before and afters of some of our previous projects. To see the before images, slide the centre line of the images to the right. To see the afters drag it to the left.

Brake Press Cylinder

Centre Joint

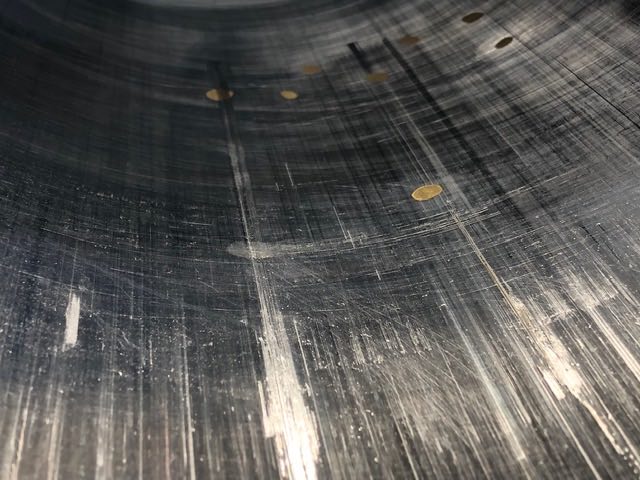

Weld Damage

Corrosion Repair and Protection

Oil Pump Shaft